This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Medical Devices

Friction Enhancement to Skin

THE TECH

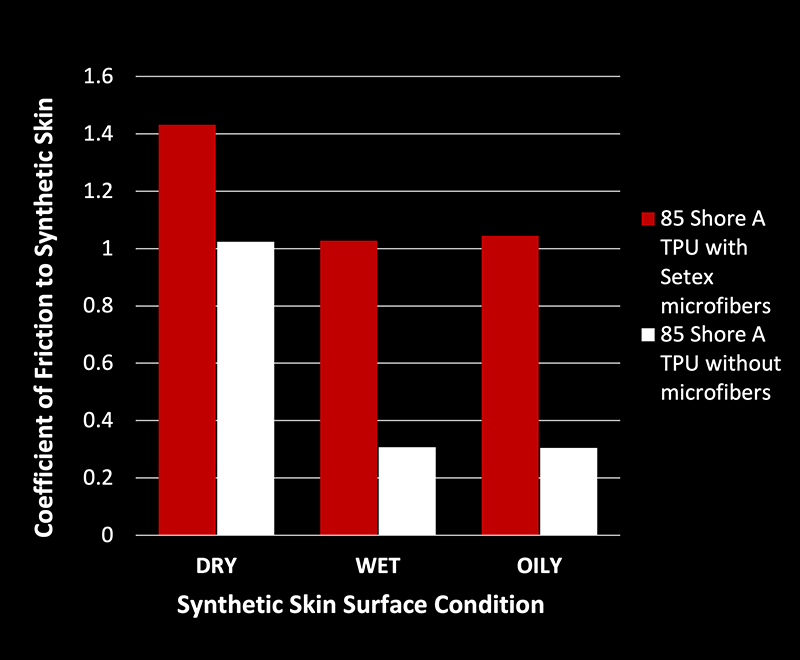

Setex’s grip is a high friction microfiber surface inspired by the microscopic hairs, or setae, of a gecko’s foot. The microfiber tips provide enhanced friction, and the gaps of space present between the fibers in the array function to wick away fluids like sweat or skin oils from the interface, improving the coefficient of friction even in these difficult conditions. The fibers also provide a comfortable feel and can reduce irritation and chafing.

These microstructures can be incorporated onto injection molded or compression molded parts with our patented tooling surfaces. Setex Technologies high friction gripping microstructures can be directly molded on our customers’ thermoplastic, polyurethane, silicone, and other moldable elastomer parts through modifications to our customer’s tooling surface. This enables our customers to use existing manufacturing partners and their own proprietary or preferred castable elastomer that already meets application-specific requirements, while gaining a significant increase in friction in wet and oily conditions.

Setex also sells material direct in a grip pad format for applications where the grip surface is to be incorporated as a secondary step. This material is produced out of a skin safe thermoplastic elastomer and has passed skin irritation and cytotoxicity testing (ISO 10993).

THE TECH

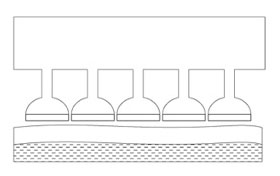

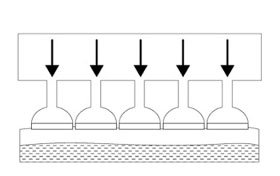

Thousands of mushroom shaped fibers mimic geckos’ toe hairs – i/e/ setae.

Flexible Setex fibers provide soft, confortable contact to skin.

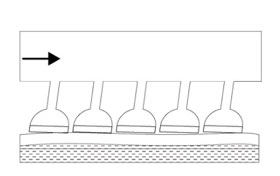

Setex’s microstructures provide a secure grip in wet and oily conditions.

Use Case Example: BoneFoam’s Lateral Lumbar Positioning Solution

BoneFoam® uses Setex’s gripping material applied to straps to replace annoying, sticky, and time-consuming medical tape on their product, a Lateral Lumbar Positioning Solution.

Setex’s grip allows for consistent and repeatable patient positioning, can reduce Operating Room costs by cutting down set-up time by eliminating complex tape configurations, and won’t irritate skin like tape can.

Temperature Controlled Packaging

Pharmaceutical shipments can require strict temperature regulation during transportation. Sensors or other temperature monitoring devices are used to keep track of the environmental conditions in transit, but maintaining the sensor mounting throughout this process can be difficult, as traditional mounting adhesives cannot withstand the ultra-low temperatures.

Setex tape technology incorporates a dry, non-tacky adhesive that has remarkable performance characteristics in both low and high temperature environments, making it ideal for mounting sensors in harsh temperatures where typical adhesives fail.

THE TECH

Low and high temperature performance with no degradation are a result of the mechanical nature of Setex’s dry microstructured tape. The properties of the gecko-inspired dry adhesive arise from the microstructure shape and do not rely on any glues or tacky materials that fail at low or high temperatures. Setex tapes have been shown to adhere at temperatures as low as -20C and as high as 300C.

The dry adhesive will bond to smooth, hard, clean surfaces with high shear strength, and can be easily repositioned, cleaned, and reused.