This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

High Grip Gloves

THE TECH

Racquets and Golf Clubs

THE TECH

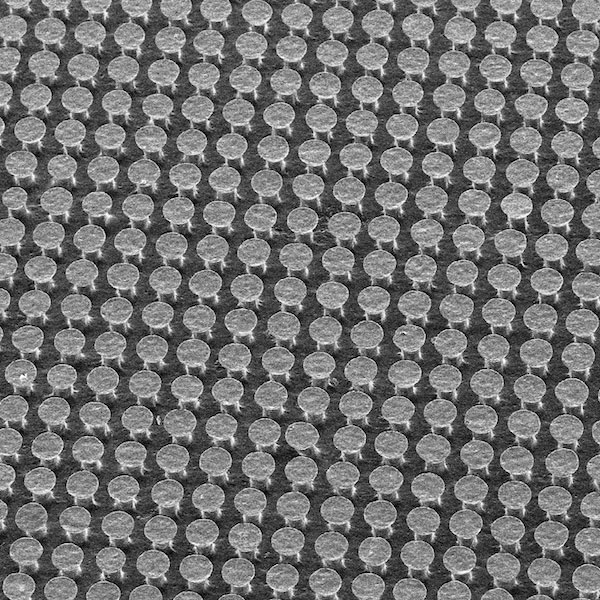

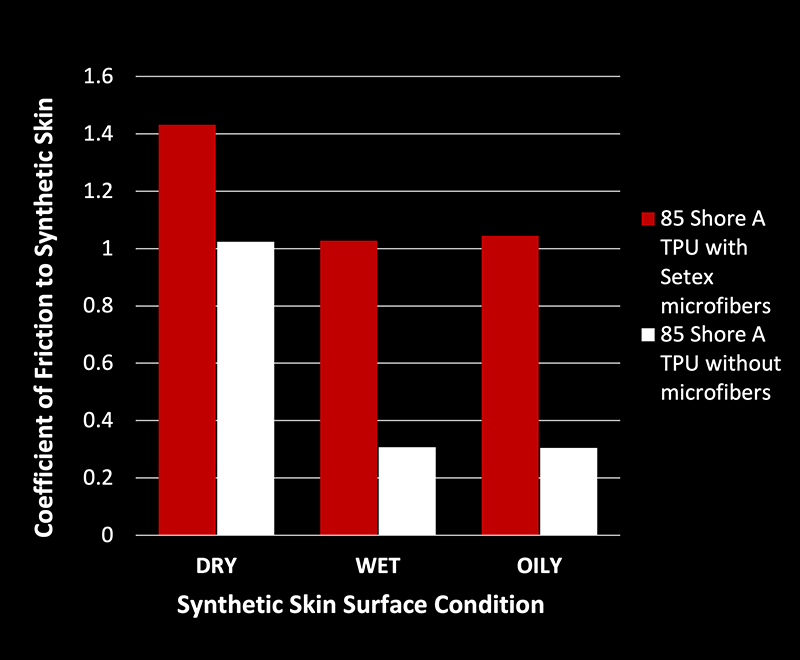

Setex’s patented high friction microfiber surface can be incorporated into injection molded parts like golf grips to enhance the friction of the surface.

Setex will treat the molding tool’s surface so that the resulting molded part is produced with high friction gecko-inspired microfibers on the surface, directly integrated and made out of the same material as the part. These molded parts, using customer plastics, gain a significant increase in the coefficient of friction, typically over 200% to skin in wet and oily conditions.

Sportswear and Socks

THE TECH

Setex’s patented high friction microfiber surface can be incorporated into injection molded parts like golf grips to enhance the friction of the surface.

Setex will treat the molding tool’s surface so that the resulting molded part is produced with high friction gecko-inspired microfibers on the surface, directly integrated and made out of the same material as the part. These molded parts, using customer plastics, gain a significant increase in the coefficient of friction, typically over 200% to skin in wet and oily conditions.